Product classification

Centrifuge

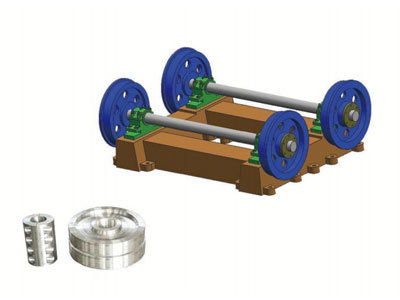

main products: five-piece set and seven-piece set of pipe pile square pile tensioning, large diameter 800-1400 pipe pile internal and external tensioning parts,

Classification:

Product Description

| Technical Parameters | ||||||||||||||||||

| Equipment Name | Applicable pile type | Centrifuge group number | Applicable mold length | Spindle | Bracket |

Motor (infinitely variable speed control) |

Base | With or without brake | ||||||||||

|

Material |

Diameter |

Material |

Diameter | Retaining Edge | Pavement Width | Brand | Specification | Power | Size | Material | Machining method | Assembling axis ask distance | ||||||

| Centrifuges | Pipe pile |

φ300-600 |

8 groups |

15m |

45 |

125 |

ZG40Mn2 |

600 |

Fabrication |

95 |

Baird or similar brands |

|

90KW |

(950-1050)*1540 |

Q235A |

Weldment |

950 |

NO |

|

40Cr Characterization |

45Tempering of forgings |

Active curb |

|

90KW |

ZG35 |

Castings |

||||||||||||

|

φ600-800 |

45 |

140 |

ZG40Mn2 |

Fabrication |

|

132KW |

Q235A |

Weldability |

1050 |

|||||||||

|

40Cr Characterization |

45Tempering of forgings |

Active curb |

|

132KW |

ZG35 |

Castings |

||||||||||||

| Empty square |

φ300-400 |

45 |

125 |

ZG40Mn2 |

Fabrication |

|

90KW |

Q235A |

Weldability |

950 |

||||||||

|

40Cr Characterization |

45Tempering of forgings |

Active curb |

|

90KW |

ZG35 |

Castings |

||||||||||||

|

φ400-550 |

45 |

140 |

ZG40Mn2 |

Fabrication |

|

132KW |

Q235A |

Weldment |

1050 |

|||||||||

|

40Cr Characterization |

45Tempering |

Active curb |

|

132KW |

ZG35 |

Castings |

||||||||||||

| Electric pole |

φ190-430 |

45 |

125 |

ZG40Mn2 |

Without barrier |

85 |

|

55KW |

0235A |

Weldment |

950 |

|||||||

|

40Cr Characterization |

45Tempering of forgings |

Without barrier |

|

55KW |

ZG35 |

Castings |

||||||||||||

| Relationship between the equipment before and after the production line: centrifugal process for fabric-finished molds | ||||||||||||||||||

Centrifuge is the use of centrifugal action, separation of liquid and solid particles or liquid and liquid mixtures in the components of the machinery. It is mainly used to separate solid particles from liquids in suspension, or to separate two liquids of different densities and immiscible in emulsion (e.g., separating cream from milk); it can also be used to exclude liquids from wet solids, e.g., shaking out wet clothes in a washing machine; special ultra-speed tubular separators also separate gas mixtures of different densities, e.g., concentrating and separating gaseous states.

Centrifuges have a cylinder, called a drum, that rotates at high speed around its own axis, usually driven by an electric motor. The measure of a centrifuge's separation capacity is the centrifugal separation factor, whose value is the ratio of centrifugal acceleration to gravitational acceleration. Industrial centrifugal separators can be categorized into three types: filter centrifuges, sedimentation centrifuges and separators according to their structure and separation requirements.

Centrifuges are widely used in many fields such as chemical, petroleum, food, medicine, environmental protection and so on. For example, in the pharmaceutical industry, centrifuges are mainly used for the preparation of vaccines, cell culture media and other biological products; in the food industry, centrifuges are mainly used to separate fruit juice, dairy products, etc.; in the environmental protection industry, centrifuges are mainly used to deal with sewage, waste gas and so on.

Precautions for the use of centrifuges include: before use, the drum should be checked for cracks, serious corrosion or deformation and other defects; the balance of the drum should be checked regularly to ensure its stable operation; when loading, the amount of material should be controlled so that it does not exceed the maximum loading line; in the process of operation, overloading or over-speed should be avoided to avoid damage to the equipment or safety accidents; after use, the centrifuge should be cleaned in a timely manner and keep it dry.

The above content is for reference only, for more information, it is recommended to consult the centrifuge related books or consult the relevant professionals.

main products: five-piece set and seven-piece set of pipe pile square pile tensioning, large diameter 800-1400 pipe pile internal and external tensioning parts, large pile adapter, pneumatic sling, centrifuge complete machine and accessories, pumping full-automatic production line, kettle entering car, mold clamping flat car, friction wheel, full-automatic feeding machine, material dividing car, mold clamping screw, high-strength spring screw, anti-pulling screw and other concrete pipe pile supporting products.

Keywords: Cloth car | Cloth system | Steam car | Electric flat car

More products

Online Message

Our staff will contact you within 24 hours (working days). If you need other services, you can contact us directly.